Magazines join fight against single-use plastics by looking into alternatives to polybagging

Screenshot: MIT Technology Review

Earlier this year, The Guardian announced it was moving to compostable wrapping called Bioplast 300 derived from potato starch which replaced its polybag wrapping. “The decision to do away with our plastic wrappers came at a time when the Guardian was trying to cut costs, and when we had just completed a transition to the new tabloid format, so it had to be as inexpensive as possible. In the end, the overall wrapping cost has gone up a little, but we see it very much as an investment and decided to invest in compostable wrapping despite increasing our operations costs,” said Mylene Sylvestre, director of publishing at The Guardian, in a Guardian article.

News UK, part of News Corp, switched polybagging for biodegradable wrapping for The Times and The Sunday Times in May, part of the company’s pledge to remove all single-use plastic wrapping by 2020.

The news titles were following in the footsteps of The National Trust’s magazine, which sent out Bioplast 300-wrapped magazines in summer 2018.

Alternatives, costs and challenges

Polybags have been used for years to distribute magazines, advertisements, subscription offers, and other materials without damage. The majority of polybags are made from polyethylene, which is a light, versatile polymer. Polybags are lightweight, strong and durable. And while there can be cost considerations, high-speed, high-volume polywrapping has made inserting magazines and other material into a polybag, affixing a label and address, a mere matter of seconds.

Polybags might be recyclable, but there often is confusion around recycling them. The ability to recycle them varies from country to country. In the UK for example, there are 39 different rules for plastics recycling, according to Printweek.

“While polythene is fully recyclable and has a relatively low carbon footprint, the facilities, capabilities and approaches to recycling differ between local authorities up and down the country. In most areas, readers needed to take the wrap to a supermarket to be able to dispose of it responsibly,” Country Life managing director Steve Prentice noted in a release.

In May, the MIT Technology Review looked into options for making the publication more environmentally friendly after putting out an issue on climate change. Alice Dragoon, senior editor of MIT News at MIT Technology Review detailed the in-depth look into alternatives in a column. “MIT Technology Review mails out 170,000 copies of each of its six annual issues. We spend over US $730,000 a year just on distribution, a sizable part of our annual budget. Polybags are extremely durable, lightweight, and cheap,” she wrote.

They were looking for long-term, sustainable and cost-effective replacements. They explored biodegradable plastic, paper and paper envelopes. Dragoon wrote of trialing paper or biodegradable plastic and of educating subscribers about recycling polybags.

|

Screenshot: MIT Technology Review

Alternatives to polybags are out there – there is compostable magazine wrap, described by AMS Mailing Systems as “a by product of potato chip and crisp manufacturing (waste potato) left out of the food chain in Eastern and Northen Europe.”

In addition to using compostable material, magazines are also swapping their polybags for paper wrappers. In May, Immediate Media’s BBC Countryfile and BBC Wildlife magazines partnered with Ecotricity and switched to a sustainable paper wrap. In late July, Hearst UK pledged to replace its plastic polybags with sustainably-sourced paper wraps on all of its print magazines by January 2020.

|

Screenshot: Hearst Magazines UK

As well, TI Media’s Country Life is delivering all of its UK-based subscriber editions in sustainably-sourced paper wrap, as of 24 July, in partnership with printer Walstead UK. “More so than ever before, our readers are becoming advocates for our environment and that ethos should come through in everything we do. They are making changes to address their environmental impact and now they can rest assured that their subscription to Country Life is that bit kinder to the planet, too,” said Mark Hedges, Country Life editor, in a release.

Uppercase

In Canada, Uppercase magazine publisher Janine Vangool is switching her polybags for kraft mailers. Uppercase, which uses 100 per cent post-consumer recycled paper on the interior pages, is a print quarterly for the creative and curious with content inspired by design, illustration, typography, craft and creative living.

Vangool announced she was making Uppercase plastics-free in June. She sees the decision as an investment into the future. “I’ve been thinking about it for a while and doing research behind the scenes,” she explained. “Going plastic-free is just something that I feel compelled to do. I knew that when I set out to make Uppercase plastics-free that was going to cost me more, I just realised that ahead of time. So, I was prepared for how much it was going to cost me, and then I just defined an amount that I could at least cover this first round.”

The Alberta-based publisher, editor and designer researched various options, from recycled and reusable plastic bags, to biodegradable mailers made from compostable corn and wheat straw, to various kinds of kraft envelopes. “I didn’t feel comfortable with choosing any of those, because I was reading contrasting reports on their pros and cons and I just thought, I don’t want to do plastics at all, it would be great if we could be plastics-free, so I returned to the material that I know and love,” she said.

Vangool chose a kraft envelope, which was made of 100 per cent recycled material and completely recyclable and compostable. She said she would give it a try for the summer issue, see how it holds up, whether it protects the magazine, and what her readers think of it. “I’ll gather their feedback and then go from there,” she said, adding that she asked her readers to reuse the envelope.

Going plastic-free will cost Vangool roughly $4,500 more per issue because of the additional cost of labour required to insert the magazine into the new envelopes.

In addition, Vangool sent out a newsletter to her audience announcing the decision to swap polybags for a compostable alternative in June, and got lots of response back. “I think over 80 people emailed me back with support, saying, ‘I’ll pay more for a subscription,’ and telling me what they’re were doing in their own lives to be more plastics-free and environmentally conscious,” Vangool said. “It was nice to hear people saying, ‘I’m willing to spend more on this because it’s important to me.’”

Vangool has always been conscious of her publication’s environmental footprint. The first step she made in trying to make Uppercase more sustainable in all ways was to plant trees. Vangool spends $1.20 for every subscription or renewal on a tree. “In January 2018, I started to purchase trees for tree planting, on behalf of all the trees who have serviced our wonderful paper product over the years, through a Calgary-based company,” she explained.

National Geographic

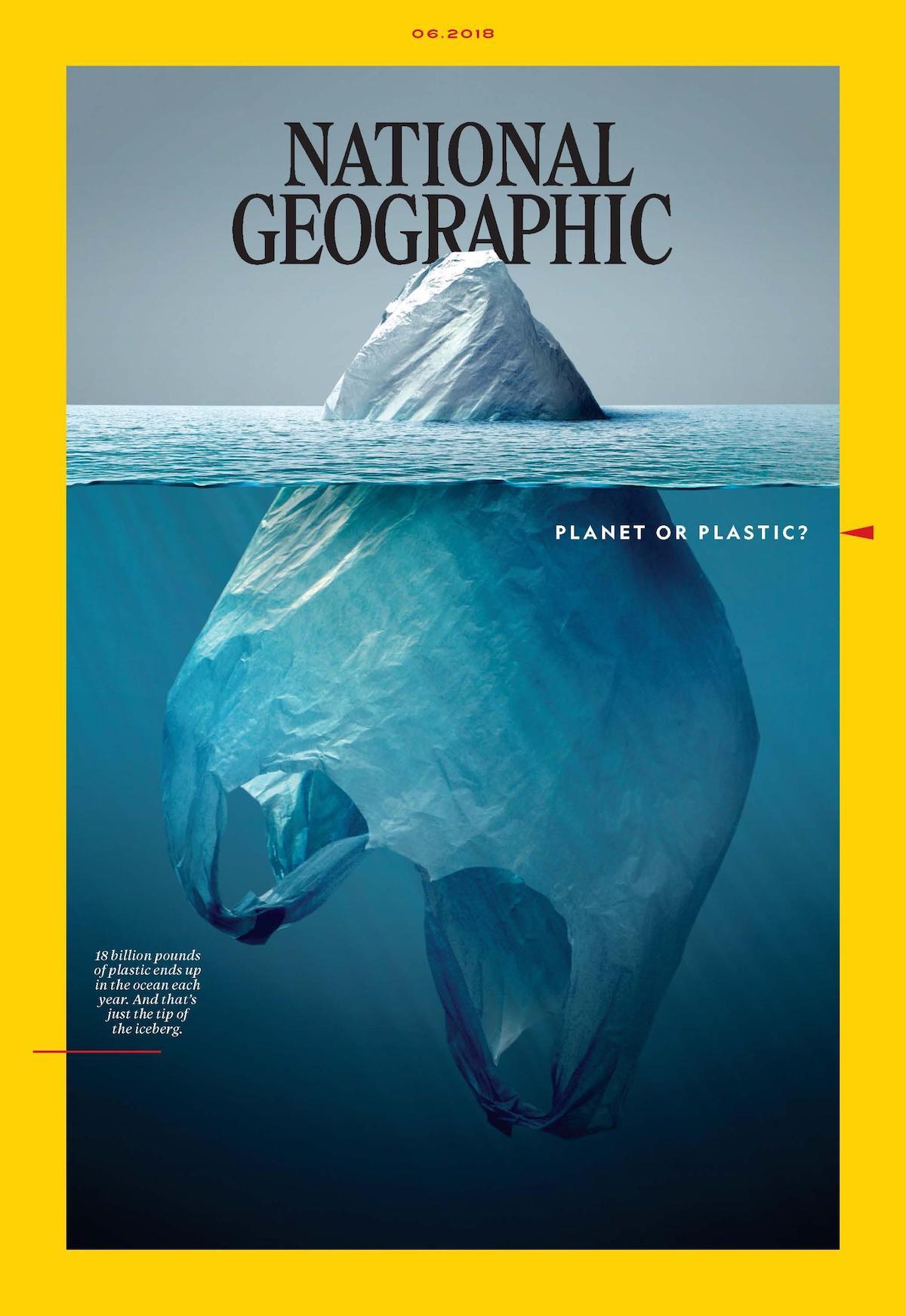

US-based National Geographic has also switched out their polybag wrapping for a paper alternative. In June 2018, together with a single-topic plastic issue of the magazine, National Geographic launched a multi-year initiative aimed at reducing the amount of plastic waste reaching the world’s ocean, said Marcelo Galdieri, SVP, brand and franchise operations.

“Our ‘Planet or Plastic’ initiative asked consumers to make a choice between saving the planet and single-use plastic,” he said. “For us to ask consumers to make that choice, we needed to set the example. One of National Geographic’s key brand attributes is our authenticity. Consumers trust what we say. So if we were asking them to choose the planet, we could not continue to send out our own magazine wrapped in plastic. We had to find an alternative.”

Galdieri said National Geographic’s brand, publishing and production teams worked with printing partner Quad Graphics to identify a solution. “Some of our markets, Canada for example, were already using a paper wrapper, so after a few months of research, we found a similar solution that worked for our American, UK and India editions,” he said. “For the first time in nearly 12 years, we sent out our magazine wrapped in paper, and with the message ‘Will this paper wrap save the planet? No, but it’s a start.’ We also asked all our international licensees to find an alternative that moves away from the poly bags, and become part of this movement with us.”

|

Screenshot: National Geographic

Like others who made the switch, National Geographic anticipated there would be additional costs to transitioning to paper wrapping. “However, we needed to find a solution that made business sense,” Galdieri said. “Working with our printing partner, we analyzed several alternatives — from belly bands, to fugitive glue, and several different types of paper — until we found an alternative that was cost neutral, if we printed in black and white. However, we decided on using a full color wrapper, which brought the cost to approximately 25 per cent more than the poly bag version, in order to meet the high standards our consumers expected from our brand and products. This also created an Ad Sales opportunity for this space which could help offset the incremental cost.”

National Geographic’s paper wrap is sourced from sustainably managed forests and is fully recyclable. Their cover wrap is a 60lb, 100 per cent PEFC-certified paper that is fully recyclable, light enough to be mindful of mailing costs, while durable enough to pass through USPS and preserve the magazine, Galdieri said.

“Switching just our English Edition, which is produced in the US and sent to the UK, India and other countries, is saving more 2.5 million single-use plastic bags per month.”

National Geographic did not make this decision lightly. The publication encountered challenges along the way, according to Galdieri. “The most important challenge was preserving the consumer experience. Many of National Geographic magazine’s readers hold onto each issue as a collector’s item, so the paper wrapper needed to preserve the quality of the magazine in multiple different environmental conditions,” he said. “The effort to switch from plastic to paper wrappers came with a number of production implications for our leadership to consider: an increase in packaging costs, additional logistical considerations, the creative on the wrap itself, creating a sales package for this new space, among others.”

However the hardest challenge National Geographic is still facing is finding solutions that address the unique challenges its Local Language Editions face around the world, Galdieri said.

“From different delivery infrastructure, to frequent monsoons, to the need to sell magazines in bundles at newsstands, the paper wrapper solution we are using in the US does not work for everyone,” he said. “We still have an ongoing commitment to phase out single-use plastic bags worldwide, while being aware there isn’t a one-size-fits-all solution. We are still evaluating alternative options to single-use plastic that addresses the business and environmental needs while upholding our brand standards, and meeting our consumers’ expectations.”

Currently, 10 National Geographic Magazines, six Nat Geo Kids, and three National Geographic Traveler Local Language Editions have switched from polybags to paper, Galdieri said. “There are two other National Geographic Magazine licensees that are using bio-degradable plastics, which, while not ideal, is the best solution available in their markets right now. As we speak, those who have not yet found a viable alternative are actively researching options.”

|

Screenshot: National Geographic

Condé Nast

In March 2019, Condé Nast in Germany introduced sustainable packaging film made of recycled material for Vogue, Glamor, GQ and AD. The packaging from a German supplier is 100 per cent recyclable, and will reduce C02 emissions by 27 per cent annually, according to a press release. “We take our commitment seriously to actively participate in the circular economy and to improve our carbon footprint with sustainable product alternatives. The process of introducing the more expensive but sustainable packaging alternative was not without its hurdles, but in the end we were able to get all the partners involved, “said Alima Longatti, head of direct marketing and CRM at Condé Nast.

|

The April issue of Vogue in Germany, which focused on sustainabilty, was launched using the new recycled film.

For publishers considering making the swap

The publishers profiled above who have made the switch successfully, outlined that the decision comes with challenges and costs. For one, it was a personal decision, for the other, a decision based on their magazine’s mission, and for yet other publishers, the decision to swap out polybags is based on their consumers. It’s not a decision to be made without fully researching the options out there.

But, for those who have made the switch, it’s one step further in the right direction.

“Going plastics-free, it’s something that we all have to do and it’s going to be costly and it’s going to be perhaps less efficient at the beginning when you change your processes,” Uppercase Publisher Janine Vangool said. “But, I think it’s important to do. I hope that more small independent publishers like myself will also make those decisions. Approach it and find some solutions. I think readers and subscribers will appreciate it.”

National Geographic is making a stand to significantly reduce plastic pollution, using all its storytelling, products, services and scientific work to lead the work of informing consumers, identifying solutions and guiding policies around the world, Galdieri said. The swap is one of the ways National Geographic is working toward this.

“So we hope the magazine industry follows our lead and are motivated to act,” he said. “We are happy that many publications have already reached out to us asking how we made the change, and we will soon publish a white paper documenting our journey and challenges to further lead the industry to follow our footsteps and make the change, helping deliver on National Geographic’s mission to significantly reduce the amount of plastic waste that reaches the ocean.

“Making the switch from a plastic wrapper to any type of solution is not as easy as we anticipated and alone won’t save the planet. But it’s a start, and National Geographic alone won’t be able to make a global impact. We hope to inspire and show the way for other organizations, companies, and governments to do their part in tackling the global plastic waste crisis by reducing, reusing, and encouraging active recycling of plastic. We all need to choose, Planet or Plastic?”